Human Exoskeletons: Full Metal Jacket

人类外骨骼:全金属外壳

From the battlefield via the factory floor to the orthopaedic clinic, artificial bones and muscles worn outside the body are providing help and protection

从战场,车间,到骨科诊所,穿戴式人造骨骼及肌肉正为人们带来帮助与保护

Soldiers kitted up in expectation of their first taste of combat often reflect on how much of their bodies a bulletproof jacket and helmet do not cover. About 81%, it turns out. More armour than this would be impractically heavy. Indeed, many soldiers already carry at least 50kg of kit and supplies, which is more than double what America’s Army Science Board advises as the limit if damage to a soldier’s skeleton and musculature is to be avoided.

士兵全副武装期待初尝战场滋味时,总会想一想自己身上有多少地方尚未被防弹衣和头盔覆盖。事实上,这样的面积约为81%。添加更多的护甲将会过于沉重而不可行。实际上许多士兵已背负至少50公斤的装备和给养,是美国陆军科学委员会(America’s Army Science Board)建议上限的两倍还多,这一限制是为了避免损伤士兵的骨骼和肌肉。

The answer, many suggest, is a second, external skeleton, complete with artificial muscles, that would let its wearer carry far more weight without strain. Such exoskeletons, moreover, are no longer the stuff of science fiction. Interest in their uses, both on and off the battlefield, is growing.

许多人建议,解决的方法是打造配有人造肌肉的另一套外部骨架,能让佩戴者毫不费力地背负起重得多的装备。而这样的外骨骼已不再是科幻小说的素材,人们在战场内外使用它们的兴趣日渐浓厚。

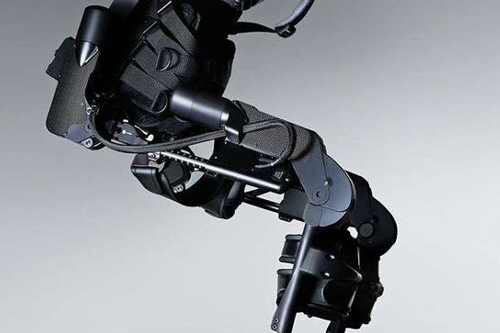

One of the most advanced is the Kinetic Operations Suit (KOS) made by Revision Military, a firm in Vermont. For a soldier this triples his armour-protection while adding little burden to his movement. An artificial articulated spine transfers most of the weight of the suit’s helmet (which fully encases the wearer’s head) to armour on his shoulders. The weight of the armour protecting his torso is similarly transferred to his hips and legs through another section of artificial spine. All this reduces strain on his neck and lower back, the natural skeleton’s weakest links. His legs must still bear the extra weight, however. To assist with this, the KOS uses titanium-aluminium shafts which are strapped, along with armour, to his lower limbs. Electric motors, taking their cue from accelerometers and other sensors embedded in the suit, move these shafts in step with the way the soldier moves his legs.

其中一款最先进的产品是由佛蒙特州的Revision Military公司制造的“动力作业套装”( Kinetic Operations Suit ,简称KOS)。该产品令士兵得到三倍的盔甲保护而不会对其行动增添多少负担。人造关节脊柱把装备头盔(完全覆盖穿戴者的头部)的大部分重量转移到肩膀的护甲上。同样,保护躯干的护甲也通过人造脊柱的另一部分把重量转移到臀部和腿部。所有这些减轻了对颈部和下背部的压力,这两处是自然骨骼中最薄弱的环节。但士兵的腿部仍须承受额外的重量。为帮助解决这一问题,KOS将钛铝合金传动装置绑到士兵的下肢上,配合盔甲使用。电动马达接收到加速度计等内置传感器的指示后,带动这些传动装置与士兵的双腿同步移动。

According to Brian Dowling, a former special-forces soldier in the American army who works for Revision Military, the system is both nimble enough and robust, enough to help its wearer run, fully laden, across uneven terrain. The armies of several countries, America’s included, are now evaluating such claims.

据如今在Revision Military公司工作的美军前特种部队士兵布莱恩·道林(Brian Dowling)所说,该系统够轻便也够结实,可帮助穿戴者在全副武装之下奔跑于崎岖地形之上。包括美国在内的多国军方正在评估这样的宣传。

A second military exoskeleton, more ambitious even than KOS, is being developed by the special forces themselves. This project’s contractors include many of the most famous names of America’s defence establishment, such as General Dynamics, Lockheed Martin and Raytheon. Intriguingly, they also include Legacy Effects, the firm that designed the exoskeletons which feature in the “Iron Man” science-fiction films. The device these firms have come up with is called the Tactical Assault Light Operator Suit, a name crafted to yield the acronym TALOS, the ancient Greek name of a mythical animated bronze statue.

比KOS更具野心的另一款军用外骨骼正由特种部队自行开发。该项目的承包商包括美国很多名头最响的防务公司,如通用动力(General Dynamics)、洛克希德马丁(Lockheed Martin)和雷神(Raytheon)。有趣的是,其中还包括了好莱坞特效公司Legacy Effects,它为《钢铁侠》系列科幻电影设计了其中引人注目的外骨骼。这些公司联手构思的产品名为“战术突击轻型作业套装”(Tactical Assault Light Operator Suit),这个名字构思精巧,其缩写TALOS正是古希腊神话中青铜巨人塔罗斯的名字。

TALOS will weigh twice as much as the soldier inside it. The components contributing to this weight will, however, make it bullet- and shrapnel-proof. They will also offer its wearer a cooling system; a set of sensors that monitor his physiology; and superhuman strength. The result, according to General Joseph Votel, head of the Special Operations Command, will be “peerless tactical capability”.

TALOS的重量将是穿戴它的士兵体重的两倍。部件虽重,却可令整套装备防御子弹和弹片。它还为穿戴者提供降温系统、一组监控其生理指标的传感器,以及超人般的力量。据美国特种作战司令部司令约瑟夫·沃特尔(Joseph Votel)将军所说,结果将是“举世无双的战术能力”。

If, of course, it works. That is not certain. To start with, the actuators that operate TALOS will need to become more agile. Replicating the movements of the shoulder joint, the human body’s most mobile, remains particularly difficult. The device will also need far more power than portable batteries can provide. General Atomics, another of the military-industrial complex’s usual suspects, has proposed designing a small internal-combustion engine to run the whole thing. But such engines are noisy, which could alert the enemy. Also, soldiers might, quite reasonably, be reluctant to wear a tank of petrol into battle.

当然,前提是它要能发挥效用,而这还不确定。首先,TALOS的致动器需要变得更灵活。要复制人体最灵活的肩关节的动作仍旧特别困难。另外,该装置耗电量大,便携电池远远不能满足。常被视为军事工业集团一员的通用原子(General Atomics)提议设计一款小型内燃机来驱动整套装备。但这类发动机噪音大,容易暴露目标。此外,士兵们也不愿“戴”着一箱汽油上战场,这很好理解。

Power down

无动力装置

A prototype of TALOS should be available by 2018, though a battle-ready version is at least a decade away. And even Revision Military’s more modest system will probably not be fit for combat for several years. In the meantime, though, the world’s armed forces are looking at the idea of unpowered exoskeletons.

TALOS的原型机应该可在2018年前推出,但能投入作战的版本至少要等上十年。就连Revision Military那套较简易的装备也未必能在几年内用于作战。不过,与此同时,各国军队正在研究无动力外骨骼的构想。

Australia’s Department of Defence, to take one example, has designed a skeleton that diverts much of the weight of a backpack, or of armour designed to protect the torso, directly to its wearer’s boots. Two steel cables – encased in flexible tubes which are, in turn, held in place by loops in the wearer’s trousers – run directly from the backpack or armour to the soles of the boots. It is these cables that transmit the load. The tubes stop them buckling, letting them support their burden while retaining sufficient flexibility for the wearer to walk or run unhindered. The system is a prototype. But two other unpowered exoskeletons, one developed by Lockheed Martin and the other by BAE Systems, a British defence giant, are already in use – not for combat, but for industry.

例如澳洲国防部设计的一款外骨架,可将背包或保护躯干的防具的大部分重量直接转移到穿戴者的靴子上。两条钢索直接把背包或护甲和靴底连接起来,钢索外面包裹挠性管,穿过裤子上的环圈加以固定。正是这些钢索起到了传输负载的作用。外裹软管可防止钢索弯曲,使其在承受重负的同时保持足够的灵活性,让佩戴者可以自如行走或奔跑。该系统仍处于原型阶段。但另外两款分别由洛克希德马丁公司和英国防务巨头BAE系统公司(BAE Systems)开发的无动力外骨骼已投入使用——用于工业生产而非军事用途。

A worker holding a rivet gun or other similarly heavy tool may have to set it down to shake out his arms and recover his strength so often that he is resting nearly half the time he is on a job. To help, Lockheed Martin has designed FORTIS, a 17.5kg unpowered exoskeleton now being tried out by the American navy and also by nearly a dozen manufacturing companies. FORTIS’s articulated aluminium frame supports a gimballed arm. One end of this arm, in front of the worker, is attached to the tool being used. The other end, behind him, carries an appropriate counterweight. Whether he is standing or kneeling to do the job in question, the combined weight of both tool and counterweight is transferred to the ground through the exoskeleton rather than through his bones. The tool itself thus seems weightless, and the worker does not so much wield as guide it. And, because that tool is attached to the exoskeleton, rather than being carried in the worker’s hands, this arrangement also prevents injuries caused by dropped tools.

工人拿着铆钉枪或其他类似的重型工具作业时,往往需要经常放下工具,甩甩手臂恢复力量,算起来,可能近一半的工作时间要用于休息。为解决这一问题,洛克希德马丁公司设计出一款重17.5公斤的无动力外骨骼,名为FORTIS。美国海军及十多家制造企业正在试用该系统。 FORTIS的铰接式铝制框架撑起一个万向臂。工人身前的万向臂一端与其使用的工具相连接。工人身后的另一端附有相应的配重。无论工人是以站姿还是跪姿操作,工具及配重的总重量会通过外骨骼而非其自身骨骼被转移到地面上。工具本身因此显得毫无重量,工人无须费力举起工具,只要引导工具进行操作。而且,由于工具是与外骨骼相连,而非由工人手持,也可防止工具掉落造成损伤。

Both FORTIS and BAE’s competing system, the Orthotic Load Assistance Device, boost productivity by about 50%, reckons Dana Ellis of the National Centre for Manufacturing Sciences. This industry body, based in Ann Arbor, Michigan, is helping both manufacturers and America’s Department of Defence adopt the technology. At American naval shipyards, FORTIS lets two workers do more with a grinder than the three-man team they have replaced, says Trish Aelker, exoskeletons boss at Lockheed Martin. At the end of their shift, she adds, workers are no longer so fatigued that they routinely “go home and crash on the couch”.

FORTIS和BAE系统公司研制的竞争产品“矫形负重辅助装置”(Orthotic Load Assistance Device)都可令生产力提高约50%,美国国家制造科学中心(National Centre for Manufacturing Sciences)的达纳·埃利斯(Dana Ellis)估计。该中心的总部位于美国密歇根州的安阿伯市(Ann Arbor),正在帮助制造商及美国国防部采用这样的技术。在美国的海军造船厂,工人利用FORTIS系统操作磨机,两人完成的工作量要比以往三人还多,洛克希德马丁公司的外骨骼项目负责人崔西·埃尔克(Trish Aelker)说。她补充道,工人下班后不像以前那样累得“一回家就瘫倒在沙发上”。

Carmakers are interested, too. Earlier this year Audi and Daimler, along with three other firms that prefer to remain anonymous, began testing a device called the Chairless Chair, made by Noonee, a Swiss firm. The Chairless Chair is a padded titanium exoskeleton that a worker straps to his buttocks, thighs and calves. Internal hydraulics allow its configuration to be locked at the push of a button, holding the wearer in a sitting position until he tries to stand up. Doing so automatically disengages the lock, permitting him to rise. The device weighs less than 4kg, so someone wearing it does not feel encumbered when standing or walking around. But, the button pushed, it lets him crouch comfortably inside the frame of a half-built car in order to add to its structure. According to Tanja Schembera-Kneifel, who runs Audi’s tests of the product, by reducing workers’ musculoskeletal problems, the Chairless Chair has also reduced absenteeism. Audi plans to deploy the device widely.

汽车制造商也感兴趣。今年早些时候,奥迪、戴姆勒和其他三家不愿公开名字的汽车厂商已开始试验由瑞士公司Noonee制造的名为“隐形椅”(Chairless Chair)的装置。这是套在工人臀部及大小腿上带有软垫的一组钛合金外骨骼。只需按下按钮,其内部的液压装置便可锁定其构型,让穿戴者保持坐姿,如果他试图站起来,装置会自动解锁。该装置重量不到四公斤,穿戴者在站立或行走时不会感动笨重不便。而只需按下按钮,工人便可以舒服地蹲坐在半完工的车架内进行加工作业。在奥迪负责测试这一产品的塔尼娅·斯坎贝拉-内费尔(Tanja Schembera-Kneifel)表示,隐形椅有助工人减少肌肉骨骼劳损,缺勤率也因而降低。奥迪计划广泛应用这一装置。

Other partial exoskeletons are in the works. One, the Personal Lift Assist Device, designed by Mohammad Abdoli-Eramaki of Ryerson University in Toronto, is also being tested by carmakers. Dr Abdoli-Eramaki’s invention involves a sheathed spring that runs down the spine. When the wearer bends to grasp and lift something, the spring stretches, reducing the effort required to stop gravity pulling his body to the floor. Then, when he stands up, the spring contracts, pulling on his torso enough to reduce by more than 15% the effort his muscles have to use to lift him.

其他局部外骨骼产品也在研发中。其中一款是多伦多瑞尔森大学(Ryerson University)的穆罕默德·阿卜杜力-埃拉玛吉(Mohammad Abdoli-Eramaki)设计的“个人抬举辅具”(Personal Lift Assist Device),也正由汽车制造商测试。这一发明包含一组带护套的弹簧,沿脊椎分布。穿戴者弯腰抓取并提起物件时,弹簧伸长,减少身体抗衡地心引力所需的力量。而要站起来时,弹簧收缩,有助拉起躯干,让身体站直所需的肌肉力量可减低超过15%。

Another partial skeleton, unveiled earlier this year by researchers at Carnegie Mellon University, in Pittsburgh, is called the Walking Assist Clutch. It is worn around the ankle and the calf, and uses a short elastic cord to reduce the work required of the muscles that pull on the Achilles’ tendon of one foot while the other is in the air. As the cord stretches, it stores energy which, a moment later, is released to tug the heel up, helping that foot push off the ground. According to its inventor, Steven Collins, the Walking Assist Clutch decreases the effort involved in walking around by 7%. For someone like an infantryman, that would be a valuable gain.

另一款局部外骨骼是今年早前在匹兹堡亮相的“助行脚套”(Walking Assist Clutch),由卡内基梅隆大学(Carnegie Mellon University)的研究人员研发。该产品穿戴在脚踝及小腿上,利用一根弹性短绳减少在一只脚悬空时另一只脚的肌肉拉动跟腱所费的力气。短绳在拉伸时储存能量,随后释放用于拉抬脚跟,帮助那只脚推离地面。其发明者史蒂芬·柯林斯(Steven Collins)表示,“助行脚套”可让步行省力约7%。对于步兵等人群,这将是宝贵的助力。

Step up

快步前行

In the end, though, the future of exoskeletons probably does lie with powered versions. The European Union, for example, is putting €15m ($17m) into a transnational project to develop a system called Robo-Mate. This is an exoskeleton with upper- and lower-arm motors that reduces the perceived weight of an object by 90%. Trials begin in 2016. One of the guinea pigs is Fiat, another carmaker (whose chairman, John Elkann, sits on the board of The Economist’s parent company). The second is INDRA, a French firm whose business is the even-more-labour-intensive one of dismantling and recycling vehicles.

但最终,外骨骼的未来也许还是要看有动力版本的开发。比如,欧盟正向一个跨国项目投入1500万欧元(1700万美元),研发名为Robo-Mate的系统。该产品是一套配备上臂及前臂电动机的外骨骼,能减少物体90%的感知重量。试验于2016年开始。另一家汽车制造商菲亚特(其董事长约翰·埃尔坎[John Elkann]是《经济学人》母公司董事会成员)是参加试验的厂商之一。另外还有主营车辆拆解及回收的法国公司INDRA,其业务更是属于劳动密集型。

Nor is Robo-Mate alone. Power Loader from Activelink, a subsidiary of Panasonic, a Japanese company; Hal from Cyberdyne, another Japanese firm; and the Body Extender from Percro, a robotics laboratory at the Scuola Superiore Sant’Anna in Pisa, Italy, are all in development, too. They may do more than make existing workers safer and more productive. Carmen Constantinescu, Robo-Mate’s project manager at the Fraunhofer Institute campus in Stuttgart, Germany, observes that they will also redefine who can become a worker. By abolishing the strength advantage enjoyed by men, exoskeletons will open up to women jobs that many now find too strenuous. They will also help older men, who might otherwise have to give up work.

Robo-Mate也并非独苗。正在研发中的设备还有日本松下的子公司Activelink的“强力装卸器”(Power Loader)、另一家日本公司Cyberdyne开发的“混合辅助肢体”(HAL)、意大利比萨市的圣安娜高等学校(Scuola Superiore Sant’Anna)的机器人实验室Percro开发的“身体扩展器”(Body Extender)。这些器材的作用也许还不止于帮助工人更安全高效地作业。在德国弗劳恩霍夫研究所(Fraunhofer Institute)斯图加特校区负责Robo-Mate研发项目的卡门·康斯坦丁内斯库(Carmen Constantinescu)观察到,这些产品还将重新定义胜任工人的资格。外骨骼器械消除了男性的体力优势,使得女性有机会从事如今觉得费力的工作。它们也会帮到那些原本不得不放弃工作的年长男性。

The group whose lives may be changed most by powered exoskeletons, though, are paraplegics. Both ReWalk Robotics, an Israeli firm, and Parker Hannifin, of Cleveland, Ohio, make devices that consist of an artificial pelvic girdle sporting two powered, jointed, limb-like appendages that strap to the wearer’s legs. Combined with a pair of walking sticks attached to his forearms, these let a user walk for hours at a time before the batteries run out. They can even permit him to climb a flight of stairs.

然而,生活因动力外骨骼而改观最多的可能是截瘫患者。以色列公司“ReWalk机器人”( ReWalk Robotics)和美国俄亥俄州克利夫兰的派克汉尼汾公司(Parker Hannifin)生产的装置都包含一个人造骨盆,它带动固定在腿上的两条电动义肢。加上附在两条前臂上的一对拐杖,整套设备能让穿戴者在电池耗尽之前一次步行好几个小时。他们甚至可以靠这套装置上楼梯。

ReWalk’s device has been available in Europe since 2012, and in America since 2014. Parker Hannifin’s was approved for use in Europe in November, and American approval is expected soon. Exoskeletons, then, come in many guises. Some may help on the field of battle. But sometimes, conquering a staircase will be enough.

ReWalk生产的器械自2012年开始已在欧洲上市,2014年起开始打入美国市场。派克汉尼汾公司的产品去年11月获批在欧洲使用,在美国获批也指日可待。以后,外骨骼会有多种形式,有些可助人战场争胜,但有时候,帮人征服一段楼梯也就足够了。

下载:英文、中文版本